What is Manufacturing Capacity Planning Software?

Manufacturing capacity planning software aims to help manufacturing organizations forecast the projects’ demand for human resources and ensure they have enough people with the required skills to staff their projects. Also, these tools simplify the capacity planning process, increase its effectiveness, and optimize resource utilization.

Let’s take a quick look at the other benefits of adopting these solutions in manufacturing project management.

- More accurate forecasting.

Capacity planning tools equipped with predictive analytics can analyze large amounts of data and provide more accurate forecasts of resource demand.

- Facilitating productive project work.

Capacity planning software helps ensure resource availability for current and upcoming projects and reduces the risks of overload. These factors contribute to increasing team members’ productivity.

- More effective decision-making.

Capacity planning software provides insights that can be further used for resource planning, project prioritization, workload management, or making other decisions.

- Cost optimization.

Capacity planning tools optimize the capacity planning process, reducing the risks of last-minute hiring decisions and preventing managers from additional expenditures.

Therefore, capacity planning software will help manufacturers optimize their project resources, ensure resource efficiency across the whole project environment, optimize costs and resource management decisions.

Let’s now review the top 10 capacity planning solutions so that you can choose the most suitable one for your manufacturing projects and their resources.

Top 10 Manufacturing Capacity Planning Tools

1. Epicflow

Epicflow is an AI-powered resource management tool for multi-project environments with a shared resource pool. Its functionality helps business organizations optimize resource utilization across multiple projects, prevent and eliminate bottlenecks, and lead every project to successful delivery. In addition, Epicflow reduces the complexity of multi-project resource management: its functionality facilitates correct prioritization, effective resource allocation, and making data-driven decisions, which in turn contributes to consistent project flow, resource efficiency, and achieving project goals.

Epicflow integrates with project management software like Jira, MS Project, Oracle Primavera, and HRM systems plus provides custom integrations upon the client’s request. Thanks to these integrations, teams can take advantage of Epicflow’s advanced functionality without changing their familiar work environment.

Epicflow serves engineering-driven companies in the following industries: manufacturing, aerospace and defense, automotive, telecommunications, software development, healthcare, and government institutions.

Companies leveraging Epicflow have a chance to achieve the following outcomes:

- Maximizing the efficiency of limited resources;

- Streamlining workflows in a multi-project environment;

- Optimizing decision-making;

- Gaining visibility into all project and resource-related processes;

- Maintaining a single source of truth for all project participants;

- Reducing project lead times and delivering them successfully.

Capacity Planning Capabilities

Providing visibility into capacity data

Epicflow keeps all resource-related data: capacity, availability, skills, location, experience, and other attributes necessary for effective resource allocation and capacity planning.

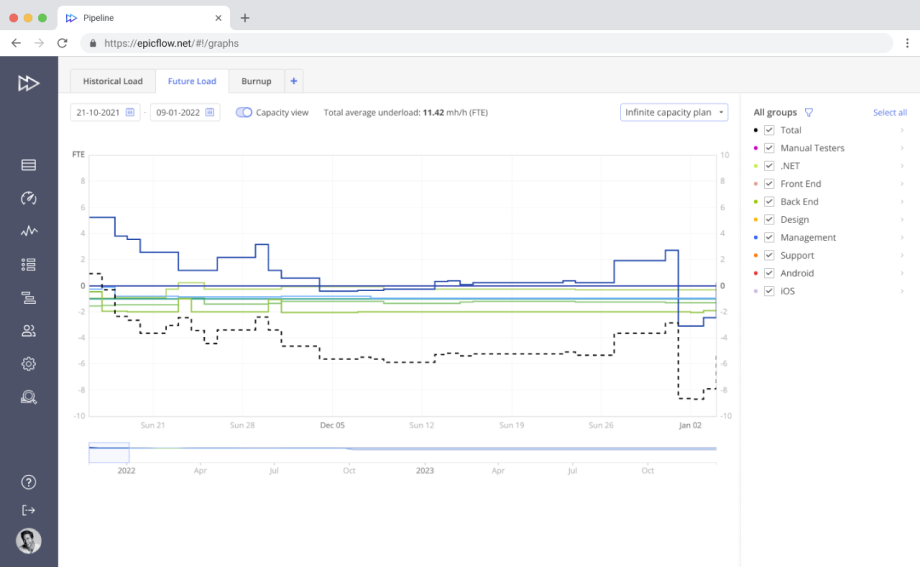

Forecasting future capacity

Epicflow is capable of visualizing team members’ future workload and capacity. This information is essential for capacity planning and allows you to assess the feasibility of an upcoming project and identify future bottlenecks.

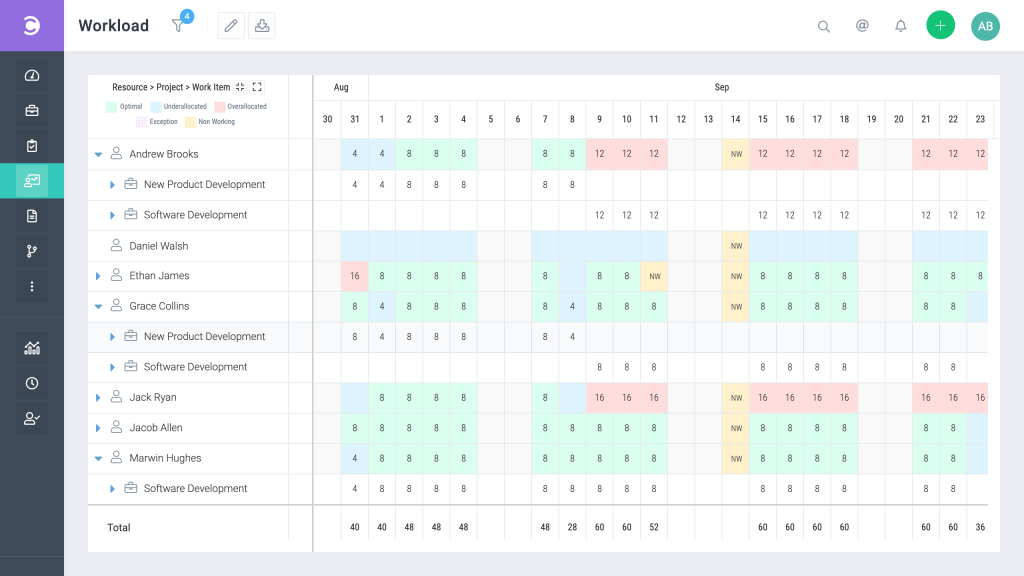

Workload management

Epicflow indicates excessive workload and provides tools to balance it with available capacity.

What-if analysis

Epicflow’s What-if analysis lets you simulate different scenarios and assess their impact on resource capacity. Also, this feature helps resolve bottlenecks and make more effective management decisions, e.g., on resource allocation, risk responses, hiring, etc.

Resource performance analysis

Epicflow provides tools to assess how resources’ output has changed over time in relation to their capacity. This allows you to assess the efficiency of team members’ work and use these insights to plan capacity for future projects.

Capacity management for project portfolio management

Epicflow’s AI-powered functionality allows you to overcome a resource capacity challenge in PPM: it helps reschedule the lower-priority projects to free capacity to complete the highest-priority ones.

Other Features

- Task and project prioritization;

- Intelligent resource allocation and competence management;

- Flexible planning for multi-project environments;

- Dynamic project scheduling;

- AI virtual assistant;

- Detecting and resolving bottlenecks;

- Progress and performance tracking on project and resource levels;

- Team collaboration;

- Budget management;

- Managing material resources;

- Reporting and analytics.

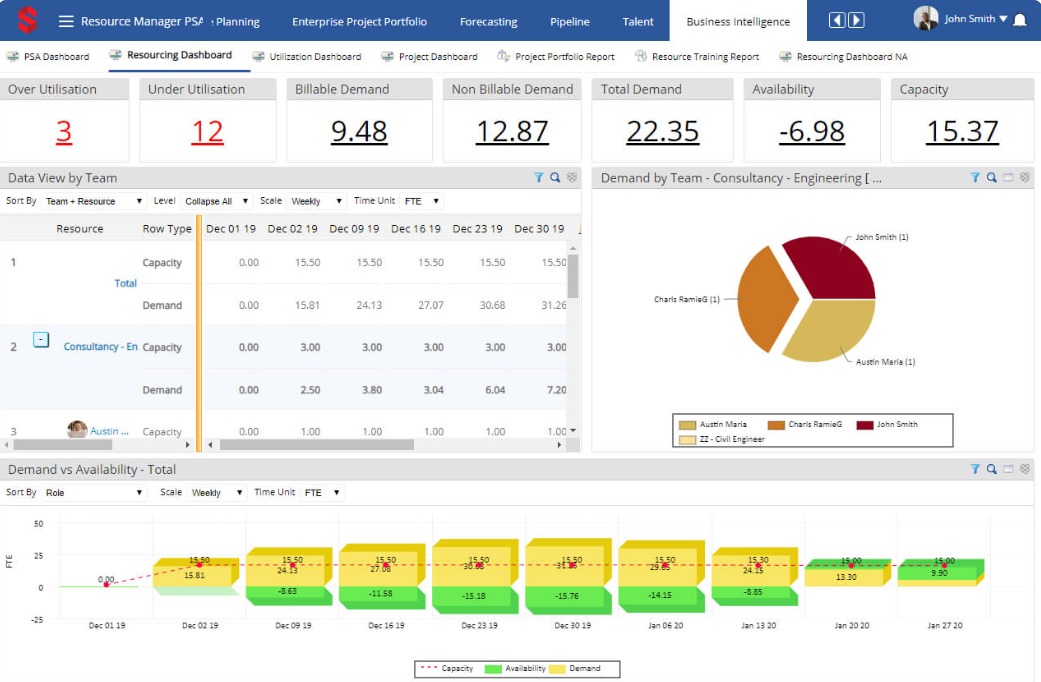

2. Saviom

Saviom is resource management and capacity planning software that aims to meet the needs of industries with dynamic project requirements. Its functionality allows business organizations to gain visibility over resource availability, forecast demand accurately, optimize the use of both human and material resources, and ensure that projects remain on track and within budget.

Saviom can be used in accounting audit and law firms, IT companies, consultancies and professional services organizations, architecture engineering and construction, etc.

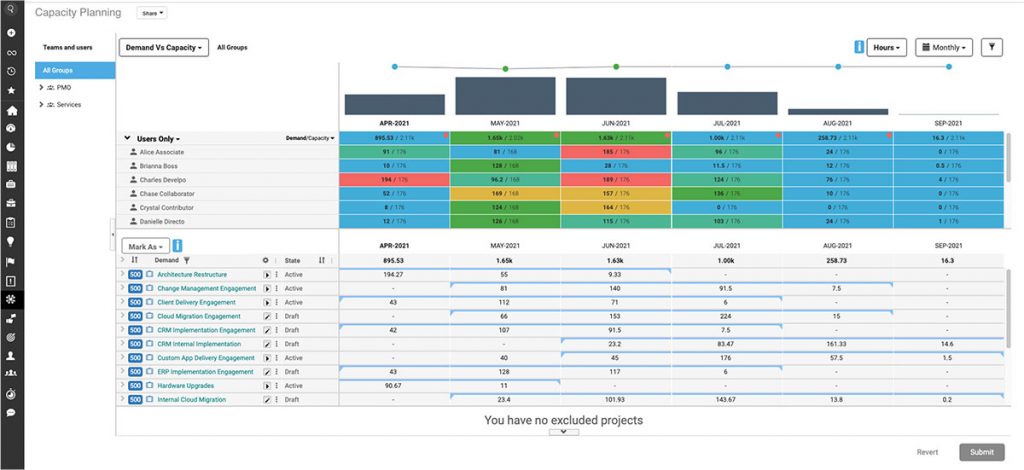

Capacity Planning Capabilities

- Forecasting workforce demand for both project and non-project activities;

- Comparing capacity vs. demand;

- Resource allocation supported by simulations;

- Forecasting resource utilization;

- Reports and analytics.

Other Features

- Resource management;

- Workforce management;

- Professional services automation;

- Project portfolio management.

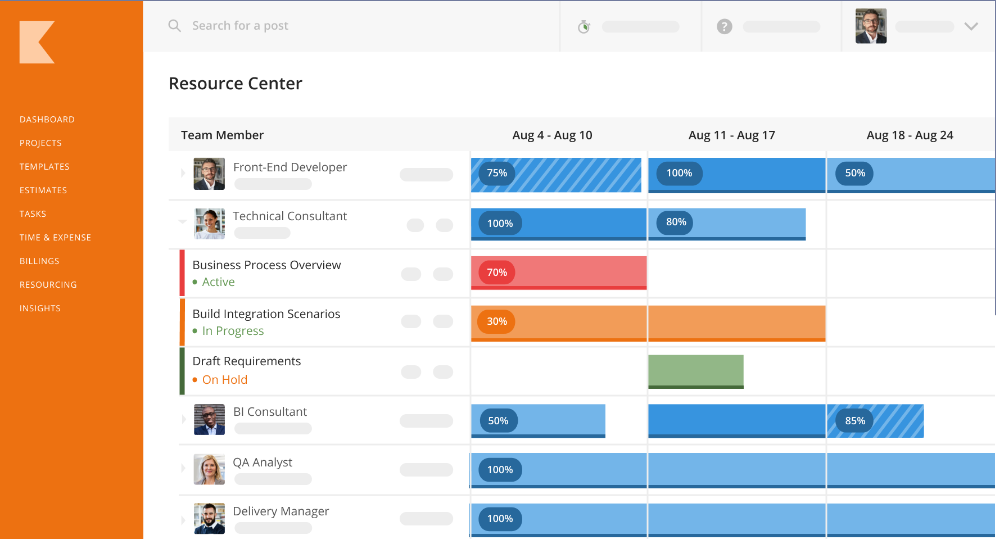

3. Kantata

Kantata is a resource and project management tool mostly oriented at companies providing professional services. The tool helps them with resource planning and allocation, resource utilization tracking, workflow optimization, and overall more effective project coordination.

Kantata supports industries including manufacturing, consulting, IT, engineering, and marketing and provides them with tools for precise resource planning and project coordination.

Capacity Planning Capabilities

- Capacity analytics with visibility into resource demand and available capacity;

- Insight into skill availability;

- Resourcing dashboard;

- Cross-project scheduling based on resource availability.

Other Features

- Resource management;

- Project management;

- Financial management;

- Business intelligence;

- Collaboration and feedback.

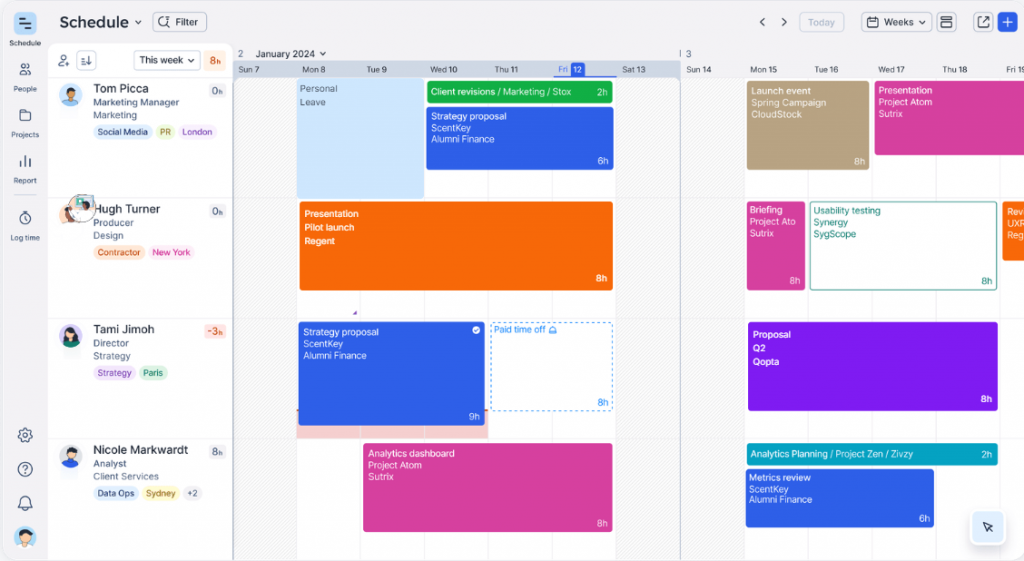

4. Float

This resource management solution helps companies optimize the resource management process in general and resource utilization in particular. It also facilitates the right resource allocation, contributes to seamless work on projects, and helps optimize project costs.

Organizations leveraging Float include consultancies, IT (software development teams), manufacturing companies, and educational institutions.

Capacity Planning Capabilities

- Visibility into employees’ availability and corresponding task scheduling;

- Forecasting resource demand and capacity;

- Providing real-time updates on resource availability;

- Managing employees’ time off and holidays.

Other Features

- Project planning;

- Resource allocation;

- Resource scheduling;

- Tracking and forecasting budget;

- Timesheets;

- Reporting.

5. Celoxis

Celoxis can be a suitable project and resource management platform for companies dealing with complex projects, timelines, and resources. It assists with optimizing project work, enhancing collaboration, project planning, and resource management.

Celoxis is widely used in industries like manufacturing, IT, consulting, and engineering, where effective capacity planning and resource allocation are critical for project success.

Capacity Planning Capabilities

- Resource forecasting based on historical data and workloads;

- Capacity and workload visualization;

- Real-time resource availability tracking;

- Facilitating demand planning.

Other Features

- Project planning and tracking;

- Project accounting;

- Portfolio management;

- Resource management;

- Reporting and dynamic dashboards;

- Client and team collaboration;

- Time and expense tracking;

- Performance analytics.

6. Planview

Planview is a comprehensive work and resource management platform. It has solutions for strategic portfolio management, project portfolio management, product portfolio management, and professional services automation. These diverse capabilities help organizations prioritize their initiatives and facilitate achieving business objectives.

Planview supports various work methodologies and is suitable for diverse teams and industries: manufacturing, engineering, IT, healthcare, and finance. We’ll consider its capacity planning capabilities as part of project portfolio management functionality.

Capacity Planning Capabilities

- Resource demand forecasting based on historical data and upcoming project requirements;

- Resource utilization tracking;

- Capacity planning based on resource availability and project priorities;

- Scenario analysis for staffing decisions.

Other Features

- Planning and prioritization;

- Strategic alignment;

- Demand capture;

- Project management;

- Team delivery;

- Financials.

7. Ganttic

Ganttic is a resource planning and scheduling tool. It assists companies with the effective administration of their resources (employees, equipment, facilities). It also contributes to more effective collaboration, streamlines project work, and helps achieve project management goals.

Ganttic can be used by business organizations of all sizes in any industry.

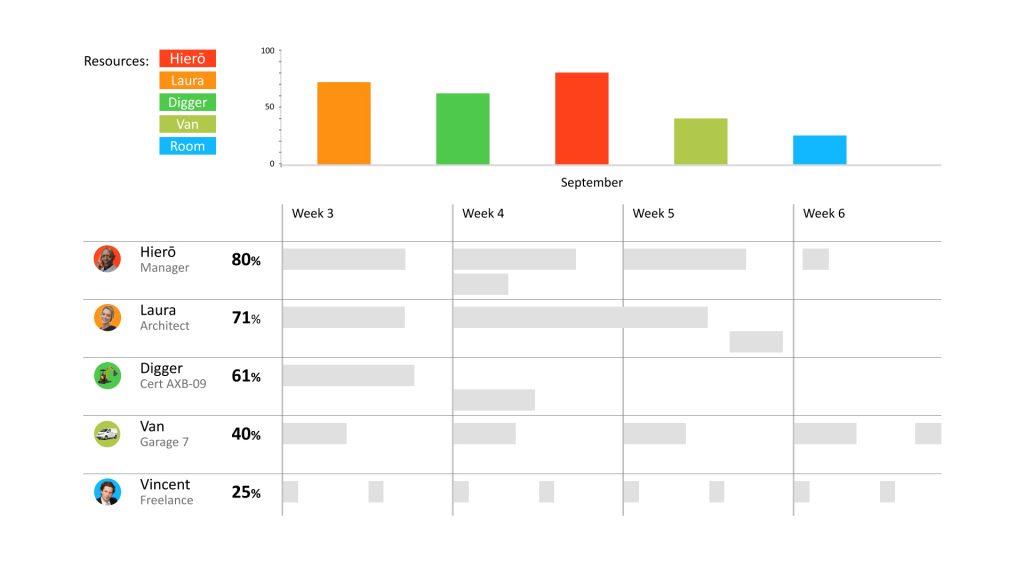

Capacity Planning Capabilities

- Balancing resource demand with available supply.

- Comprehensive overview of current and future capacity.

- Visual capacity heatmaps indicating team members’ current workload.

- Visibility into resources’ available capacity and planning projects accordingly.

- Creating and sharing capacity planning reports.

Other Features

- Resource scheduling (including equipment scheduling);

- Project portfolio management;

- Project management.

8. Wrike

Wrike is a comprehensive project management tool for planning, task tracking, and resource management. Also, the tool helps organizations plan their capacity and ensure optimal resource utilization across projects.

Wrike is suitable for the following organizations: manufacturing, construction, technology, financial services, agencies, consultancies, healthcare and educational institutions, and media and entertainment projects.

Capacity Planning Capabilities

- Visibility into current teams’ workloads and corresponding task allocation;

- Resource demand forecasting;

- Providing real-time capacity insights;

- Tracking employees’ availability.

Other Features

- Project planning;

- Milestone tracking;

- Budget management;

- Timesheets;

- Resource allocation;

- Reporting and analytics.

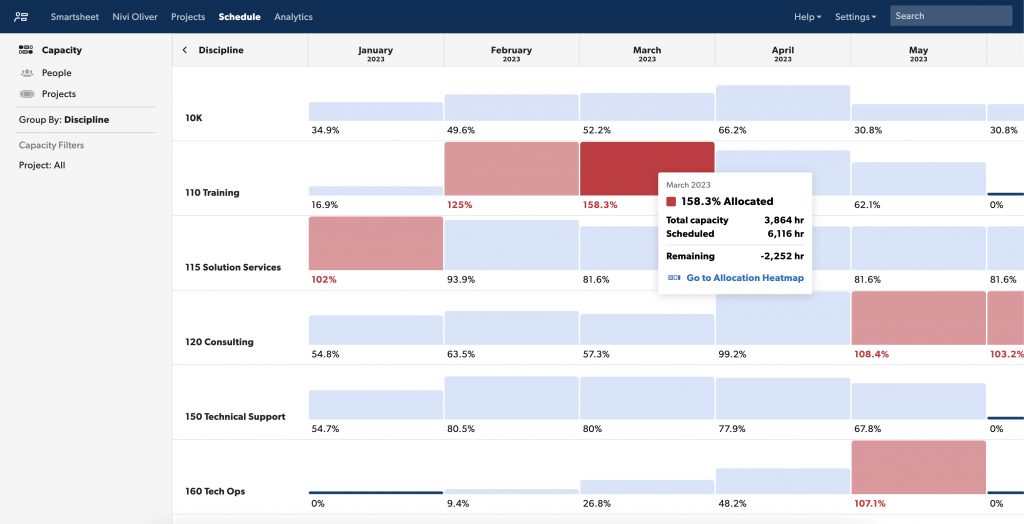

9. Smartsheet

Smartsheet is a work management platform designed to help businesses optimize their project management and increase efficiency. This becomes possible thanks to leveraging a variety of spreadsheets, automation, and resource management tools.

Smartsheet supports teams across various industries, including manufacturing, IT, marketing, and healthcare.

Capacity Planning Capabilities

- Resource allocation based on workload visualization;

- Forecasting resource capacity and demand;

- Real-time overview of team members’ capacity and workloads;

- Tracking actual vs. planned capacity;

- Dashboards and reporting displaying resource utilization.

Other Features

- Project planning;

- Automation of workflows;

- Collaboration and communication;

- Account administration;

- Digital asset management;

- Portfolio management.

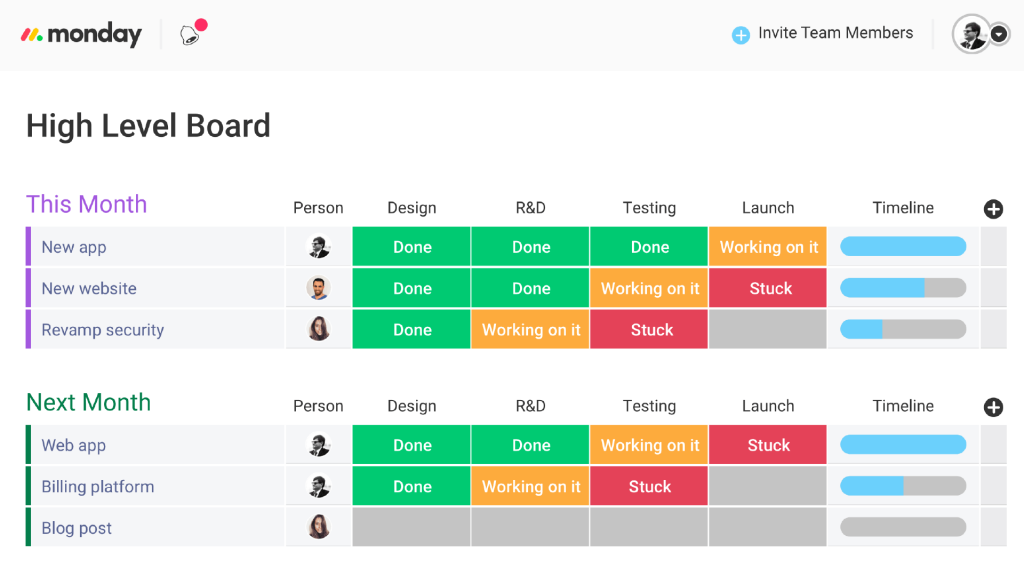

10. Monday

Monday is a work management tool that aims to simplify project orchestration and workflow management for companies of all sizes. The tool helps organizations streamline task allocation, track progress, and improve team collaboration.

Monday is used by various industries, including marketing, construction, IT, and manufacturing.

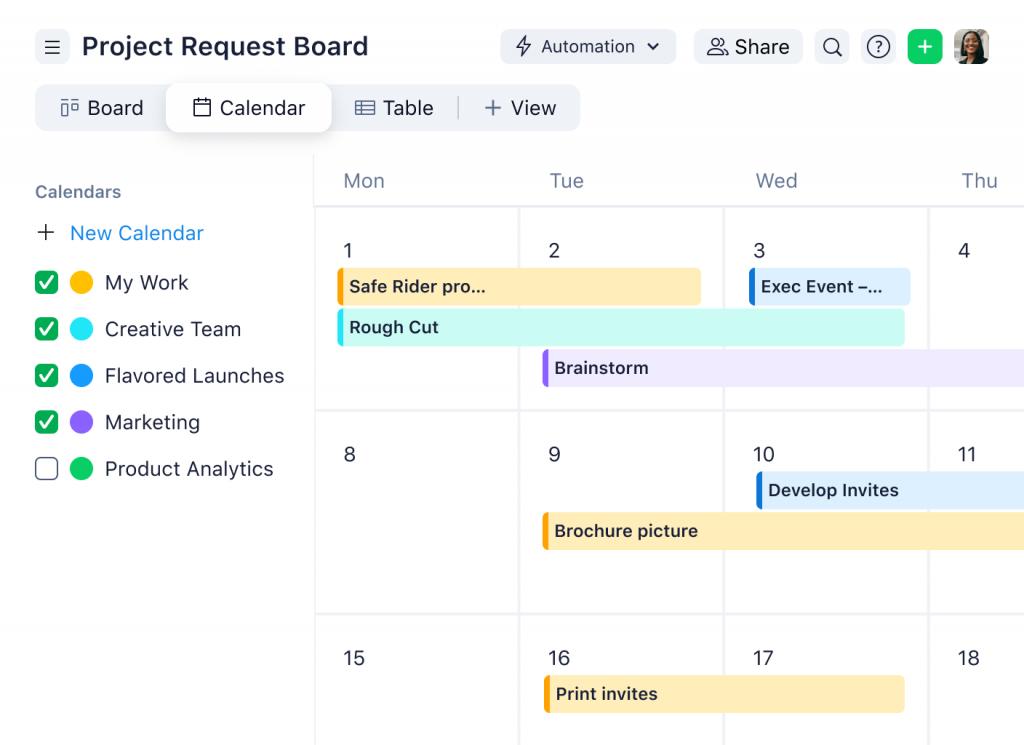

Capacity Planning Capabilities

- Workload view;

- Real-time resource availability tracking;

- Capacity visualization;

- Dashboards facilitating demand forecasting.

Other Features

- Project management;

- Task management;

- Portfolio management;

- Resource management;

- Business operations;

- Automation;

- Reporting.

All of the listed solutions have something in common, which can complicate the choice. Read the next section to learn the criteria that will help you choose the most suitable capacity planning software for manufacturing projects.

How to Select a Manufacturing Capacity Planning Tool?

Choosing the right capacity planning tool is critical for effective resource management in manufacturing projects and their successful delivery. So, we’ve prepared some tips that will help you analyze the solutions available on the market and select the most suitable one.

1. Identify your project and resource management needs.

First, you should determine what challenges and inefficiencies are in your manufacturing project and resource management. After that, you should set the goals you’re going to achieve upon adopting the manufacturing capacity planning tool: e.g., increasing resource efficiency, optimizing resource costs, enhancing the visibility of resources, etc.

2. Determine required features.

Having analyzed your difficulties and needs, you should decide what features will help you address them, Here are examples of capabilities that will help you perform manufacturing capacity planning:

- Demand forecasting;

- Visibility into resource-related data;

- Resource allocation based on skills, capacity, and availability;

- Workload management;

- Resource performance analysis;

- AI-powered scenario analysis;

- Material resources management;

- Real-time monitoring and control;

- Integration with other software;

- Reporting and analytics;

- Capacity utilization tracking.

3. Consider the tool’s scalability and flexibility.

The number of projects you are running can increase over time, so it’s a good idea to choose a solution that can be adapted to the changed needs of your manufacturing organization. Also, check if the tool is flexible enough to adjust to possible changes in the production and project flow.

4. Assess data security.

Manufacturing processes involve the application of digital technologies and interconnections between them, which makes manufacturing processes vulnerable to cyber threats. In addition, the manufacturing industry is regulated by strict requirements, including data security standards. So, make sure to protect your project data—choose a capacity planning solution that complies with data security requirements.

Read more: How to Choose the Right Project Management Tool: Selection Guide

Final Words

Manufacturing capacity planning software will help you optimize resources in manufacturing projects and ensure they are properly staffed. In addition, this software facilitates team members’ productivity, optimizes decision-making, and prevents cost overruns.

Choosing the right manufacturing capacity planning software requires careful consideration of your specific resource challenges and future needs, the analysis of required capabilities, the tool’s flexibility and scalability plus data security. Scalable and user-friendly capacity planning software equipped with predictive capabilities can significantly improve planning resource capacity for manufacturing projects, enhance their outcomes, and facilitate business growth.